Images

Videos

Olympus Portable Pugmill Systems by PavementGroup

Description

Olympus engineers and technicians are experts at building pugmill systems for professionals. Olympus is one of America's leading pugmill brands, delivering pugmills that are durable, dependable, field serviceable, and easy to operate, without allthe complexity. Choose from 80-750tph, 1-3 bins. Olympus pugmill systems serve a cross-section of industries. They're affordably priced with quick delivery times. Call us for pricing and more information: 518-218-7676. Want to chat after hours? Ask for Devin

We're experts at building pugmills. Olympus pugmills provide exceptional quality for years of dependable service. Our pugmill mixers are mindfully engineered for ease of use and field serviceability. Our prices are reasonable and won't break the bank.

Olympus Pugmill Systems are engineered for durability and ease of use. Heavy-duty construction and high-end OEM components assure reliability and years of dependable service. You get quick delivery and an affordable price that won't break the bank.

Olympus engineering and production teams have 3 generations of experience building construction equipment, and take great pride in their quality construction and workmanship.

Top-quality OEM components on every machine include Danfoss controls, Vibco vibrators, Viking pumps, Isomag flow meters, Marathon motors, Dodge reducers, SEW drives, Rice Lake belt scales.

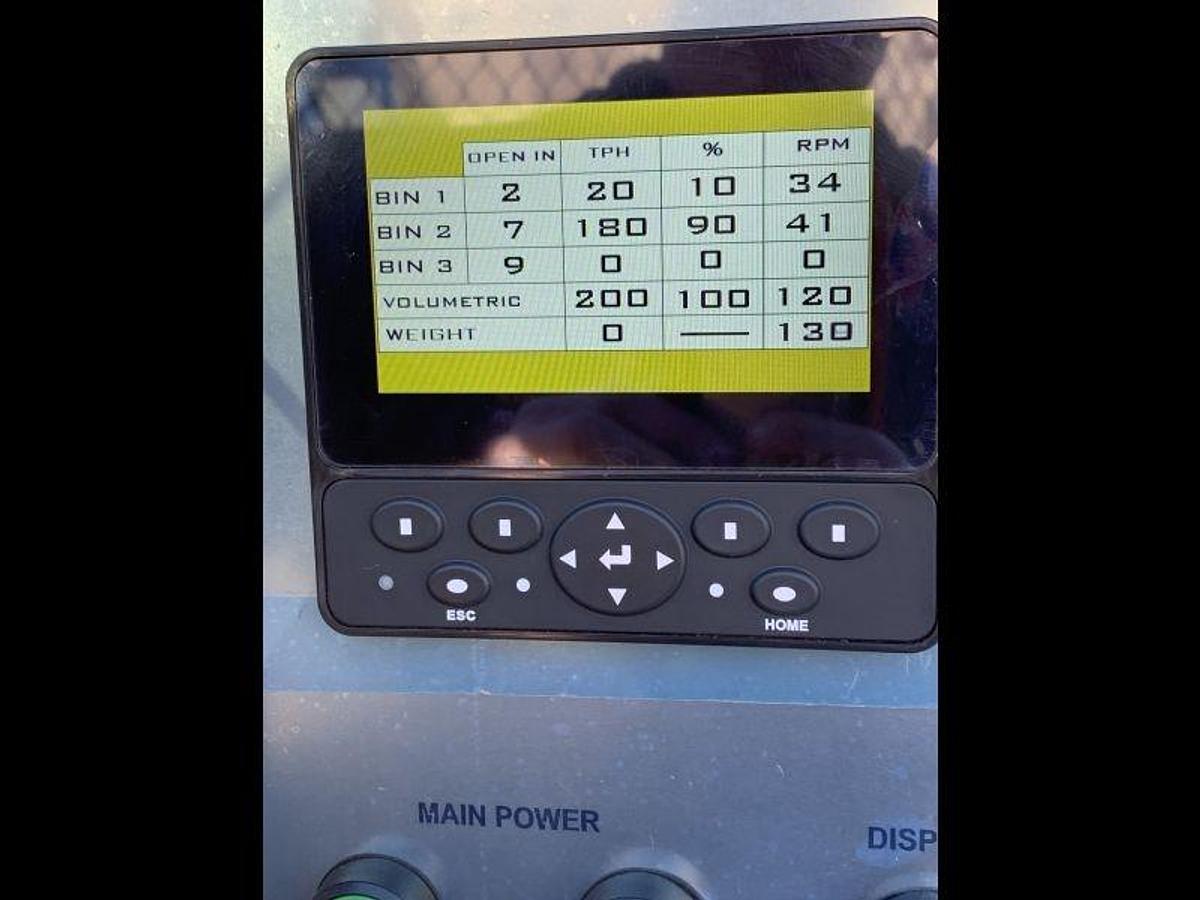

Easy To Operate Olympus pugmills and cold-feed bins use Danfoss controls, which are not complicated but rather intuitively engineered for ease of use.

Support you can count on! Our helpful parts and service teams are just a phone call away.

Quick delivery, just 4-8 weeks on most orders.

Affordably priced, won't break the bank.

Applications include soil blending, lime-treating base soil, cement-treated base, cold-patch asphalt production, soil remediation, sludge, liquid waste solidification, and more. Materials processed include aggregates, recycled asphalt pavement, roofing shingles, earthen materials, sludge, water waste, fly ash, foundry dust, coal cake, and salt. Olympus cold feed bins are used at pit and quarry sites, landfills, and other locations where materials are mixed and blended.

How do they work? Olympus pugmills combine a pugmill blending system with twin mixing shafts coupled to mixing arms and paddles, that are synchronized to homogeneously mix and move the materials. The pugmills can be combined with a multi-bin configuration, conveyor belt systems, and optional water and emulsion systems. An onboard Danfoss computer control/monitoring system allows the operator to program the mix design and monitor the output. Power to the pugmill is typically provided by a Marathon electric motor coupled to a Dodge reducer. The bin belts and collecting belt conveyors are powered by an electric motor, gear reduced with a pulley set. The system is easily monitored and controlled by an operator using the Danfoss control station. Electricity is supplied by an onboard generator, or you can connect to an auxiliary generator or 3-phase power. You can transport the pugmill by connecting to a 5th-wheel tractor. The mini-HERCULES Pugmill can be towed with a 3/4-ton pickup truck.

OPTIONAL Pugmill Equipment and Pugmill Configurations:

- Choose nominal output: 100tph, 200tph, 300tph, 500tph, 750tph

- Choose configuration: skid-mounted pugmill, or 1-3 bins

- Bins: several size and layout configurations

- Belts and Idlers: several size and trough configurations

- Bin level indicators

- Vibrators

- Air cannons

- Grizzly, manual, or hydraulically lift

- Split bin, split gates

- Water pump

- Water flow meter

- Asphalt pump with cleanout system

- Coriolis meter

- Foamed asphalt system

- Discharge conveyor, manual or hydraulic extend or folding

- Belt scale(s)

- Computer programmable logic controller (PLC)

- Computer peripheral connection

- Ticket printer

- Remote controls, blue-tooth or tethered

- Hydraulically activated legs

- Air ride suspension

- Genset onboard

- Mimic panel for generator

- Extra fuel tank

- Air compressor

- more...

Customers served include quarries, asphalt producers, salt sales operations, the oil and gas industry, soil remediation, soil cement production, and cement-treated base production. Customers include municipal and corporate entities.

Customer Applications:

Phillips and Jordan: Surge bins and cold feed bins for conveying sand for soil cement.

Quickrete: 3-bin cold feed system for storing aggregates as part of their cold mix production processing equipment.

Sustainable Pavement Technologies: producing cold mix asphalt from RAP reclaimed asphalt pavement and RAS recycled asphalt shingles, for roadway paving.

Jennings County, Indiana: blending 1/2" minus aggregate, 3% sand, and 5.5% AE-300 to produce cold-patch asphalt for paving 90 miles of secondary roads per year, as well as for winter pothole repairs. Call us for their recipe.

NJ Site & Utility: performing soil remediation, clay processing, lime treated base, replacing the final product, making suitable for building construction, processed 150,000 tons, and counting.

Petta Industries: processing waste frack materials, to remove freestanding water, passing the #6 paint filter test, and making suitable for landfilling.

Gonzalez and Sons: produced 25,000 tons of 100% recycled asphalt and paved 20 acres of their parking lots. Call us for the recipe.

Pettis County, Missouri: grant-funded pugmill purchase for cold-patch production for roadway paving construction.

Paul Reed Construction: producing its cold patch asphalt for repaving of US missile bases.

Northgate Holdings: processing, absorbing, and solidifying 150+ gallons of wastewater/minute for Waste Management landfills.

Middle Georgia Paving: making cold patch material and paving with it throughout the summer months. Call us for the recipe.

Customizable: Olympus Pugmills and cold feed bin systems can be custom-tailored with the options needed on your specific project(s), to meet a wide variety of applications across a spectrum of industries such as cold mix asphalt production, mixing fly ash, cement, and various recipes for cement treated base; remediation of contaminated soil; mixing road salts with additives; liquid waste solidification.

FOR MORE INFORMATION and PRICING, call 518-218-7676. After hours and on weekends, ask for Devin

Visit: https://www.OlympusPugmills.com

Olympus is a PavementGroup brand.

Additional information can be found at: https://www.pavementgroup.com/pugmills/

Our equipment is also available through TIPS "The Interlocal Purchasing System." For more information, please visit our listing on TIPS website. Click here to learn more!

Specifications

| Manufacturer | PavementGroup |

| Model | Portable Olympus Pugmills |

| Condition | New |

| Stock Number | Portable Pugmills - Olympus |

| Size | 10-80, 100, 300 500, 750 tph |